As part of my McKinsey 12 Disruptors impacts on the property industry I wrote about the impact of advanced materials, robotic construction and 3D printing. Fanciful school boy dreams maybe but in an industry that has a lot more money than construction some of these ‘Tony Stark’ dreams are coming true.

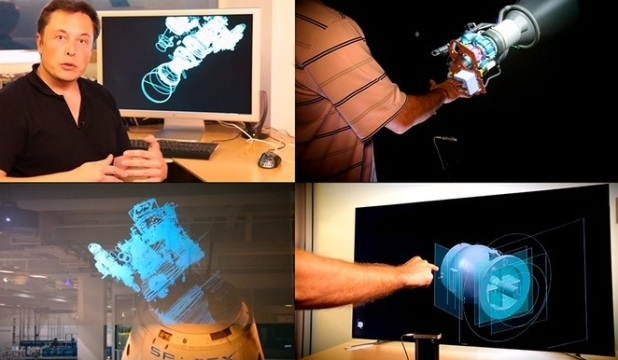

Elon Musk is involved in lots of startups, lots of companies and comes up with some amazing ideas and through his work at SpaceX he has honed those dreams into combining 3D design, motion sensing interaction and 3D printing of titanium parts to new heights. The video in the treehugger article is a must watch for awesome nerds and normal people alike.

So what does it mean for the construction?

Treehugger sums up the resource efficiency impacts really well “All manufacturing is about moving large quantities of atoms around. This takes energy, and there’s waste. But we can imagine a future where there’s a lot less material waste because 3d printers only use the amount of stuff they need, thus using a lot less energy.”

Absolutely, resources will become more and more constrained in the future as we push the boundaries of our one planet limitation.

But it will also change the way that we interact and participate in the development of our communities, cities and buildings. Imagine the impact of being able to interrogate and manipulate the design of the building before it gets built, right up until the last minute before the part gets 3D printed on site.

With your Google glasses you can walk onto site part way through construction, pull up the construction element that is being fixed next, manipulate it in real time, modify it and do a final clash check before it gets printed in the basement.

No more waste, no more variation claims because of a last minute change, no more cost overruns? Sounds awesome.